Industry News

-

There are several classifications of oil pumps

When the pump is filled with liquid, the impeller rotates to generate centrifugal force, and the liquid in the impeller channel is thrown to the periphery under the action of centrifugal force, and flows into the pump casing to form a vacuum in the center of the impeller. The liquid is sucked in by atmospheric pressure. The pool flows into the impeller. In this way, the liquid is continuously sucked in and out. The liquid that gains energy in the impeller has greater kinetic energy when it flows... Read More

21-10-2020 Industry News -

Advantages of hydraulic transmission

Compared with mechanical transmission, electric drive and pneumatic transmission, hydraulic transmission has the following advantages:1) Hydraulic transmission can realize stepless speed regulation in operation, which is convenient and has a wide range of speed regulation, up to 100:1 ~ 2000:1.2) : under the same power, the hydraulic transmission device is small in size, light in weight, small in inertia and compact in structure (for example, the weight of the hydraulic motor is only 10-20% of t... Read More

15-10-2020 Industry News -

Notes on installation and use of high pressure gear pump

The elastic coupling is usually used between the transmission shaft of high pressure gear pump and the output shaft of motor, and its coaxiality tolerance shall be less than 0.1mm; if the sleeve type coupling is selected, the coaxiality error shall be less than 0.05mm. It is forbidden to drive pump shaft directly with V-belt. The rotation direction of the gear is clearly specified, so it is not allowed to be confused during installation.Suction and drain portsIf the diameter of suction port and ... Read More

10-10-2020 Industry News -

Measures to prevent excessive oil temperature rise of gear pump

1. Select the hydraulic circuit with high transmission efficiency and appropriate adjustment mode. At present, the throttling speed regulating system of quantitative pump is generally used, and the: rate is low (< 0.385). This is because the efficiency of quantitative pump and hydraulic cylinder is about 85% and 95% respectively, and the loss of directional valve and pipeline is about 5%. Therefore, even if the flow control is not carried out, there will be 25% power loss. At least half of th... Read More

30-09-2020 Industry News -

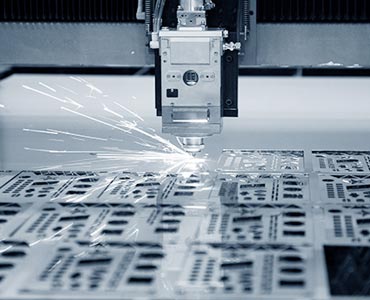

How is the electronic product shell mold made?

High pressure hydraulic gear pump and ordinary gear pump have the following differences:(1) The shape of high pressure hydraulic gear pump adopts rectangular five piece combination type, which is easy to process, neat and beautiful;(2) The noise level of high pressure hydraulic gear pump is low, and the noise value under maximum load can reach a level of product standard (ordinary gear pump is generally in level B and C);(3) The volumetric efficiency of high-pressure hydraulic gear pump can reac... Read More

23-09-2020 Industry News -

What is the difference between gear pump and hydraulic gear motor?

1、 The composition is different Gear pump: gear pump is composed of pump body, driving gear, passive gear, bearing, oil seal and gear shaft. Hydraulic gear motor: the hydraulic gear motor is composed of shell, crankshaft, port shaft, connecting rod, plunger and eccentric wheel. 2、 The working principle is different Gear pump: the working principle of gear pump is to transfer liquid or pressurize it by changing and moving the working volume formed between pump cylinder and meshing gear. Hydraulic... Read More

15-09-2020 Industry News -

Eliminate these 10 kinds of hidden dangers and ensure the stable use of hydraulic pump

If the hydraulic oil pump fails, it will affect the work of the whole system. Today, we will introduce 10 causes of hydraulic pump failure.Coupling installation errorBecause the fit clearance between coupling and shaft is too small or no clearance, the bearing will be injured when it is knocked hard, which will lead to early damage of the bearing and affect the life of the whole pump core.Coaxiality out of toleranceIf the concentricity exceeds the specified value during installation, the bearing... Read More

10-09-2020 Industry News -

Key points of hydraulic equipment maintenance

Strengthening the maintenance of the equipment is very important to ensure the normal operation of the equipment. At present, there are four problems in hydraulic equipment1. The hydraulic system works well and sometimes fails, and the actuator sometimes does not work;2. Serious system leakage;3. The actuator has jumping, vibration or crawling when it moves;4. The temperature rise of working oil in hydraulic system is too high.If the above four problems are analyzed and diagnosed to find out the... Read More

01-09-2020 Industry News -

Working principle, classification and application scope of dump truck

1、 Brief introduction:Dump truck is a vehicle that unloads goods by hydraulic or mechanical lifting. Also known as dumper. It is composed of automobile chassis, hydraulic lifting mechanism, cargo box and power take-off device.2、 Application scope of dump truckIn civil engineering, dump truck often works with excavators, loaders, belt conveyors and other construction machinery to form a loading, transporting and unloading production line for loading, unloading and transportation of earthwork, gra... Read More

25-08-2020 Industry News -

No oil from vane pump? With the outlet pressure does not go up?

Almost all the causes of the failure of "vane pump can not produce oil" may be the reason that the pressure can not go up or there is no pressure at all1. There is poor contact between the oil distribution plate and the end face (fixed surface) of the housing, and there is a large dirt between them, so that part of the pressure oil in the pressure oil chamber flows into the low-pressure area through the gap between them, and the output flow is reduced. Therefore, it should be disassembled and cl... Read More

18-08-2020 Industry News -

Improper use of vane pump

In the product manual of vane pump, there are generally detailed installation guidelines and precautions. However, in the actual use process, there are often such failures and problems. Most of these problems should be caused by improper use. Improper use accounts for more than 95% of the oil pump damage, but few of them really belong to product quality problems.1、 Improper use of several manifestations:1. Wrong installation method:A. Coupling too tight:Because the clearance between coupling and... Read More

11-08-2020 Industry News -

What are the differences in the performance comparison of gear pump, vane pump, plunger pump and screw pump?

Hydraulic pumps are divided into gear pumps, piston pumps, vane pumps and screw pumps. Each pump has its own characteristics and is applied in different mechanical or industrial equipment.I. Gear PumpPressure range: 2.5~28MPa; displacement range: 0.3~650ml*r; flow fluctuation: large; higher speed: high; volumetric efficiency: 0.7%~0.9%; total efficiency: 0.6%~0.8%; self-priming performance: excellent; noise: large; price: lowest; pollution resistance: excellent; commonly used in construction mac... Read More

05-08-2020 Industry News